PRODUCT LIST

- HOTLINE

+86 18068282588

+86 13328116360

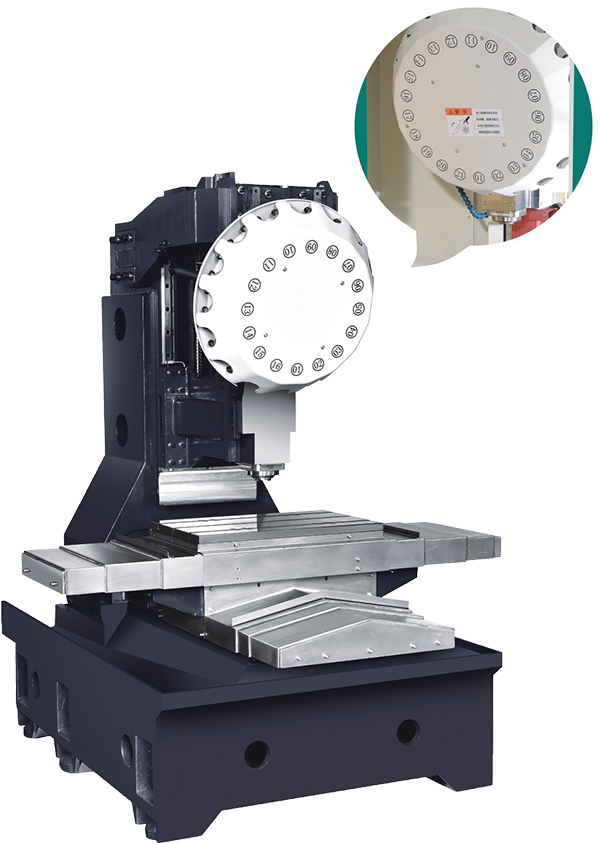

V800-L High Speed Vertical Drilling and Tapping Center Machine

Release Date:2021-04-24 10:01:39 Number of visits:192

|

Machine Characteristics

● The main structure castings are made of HT300 material, the surface hardness is not less than HB250, and they are subjected to high temperature annealing and natural aging treatment. |

|

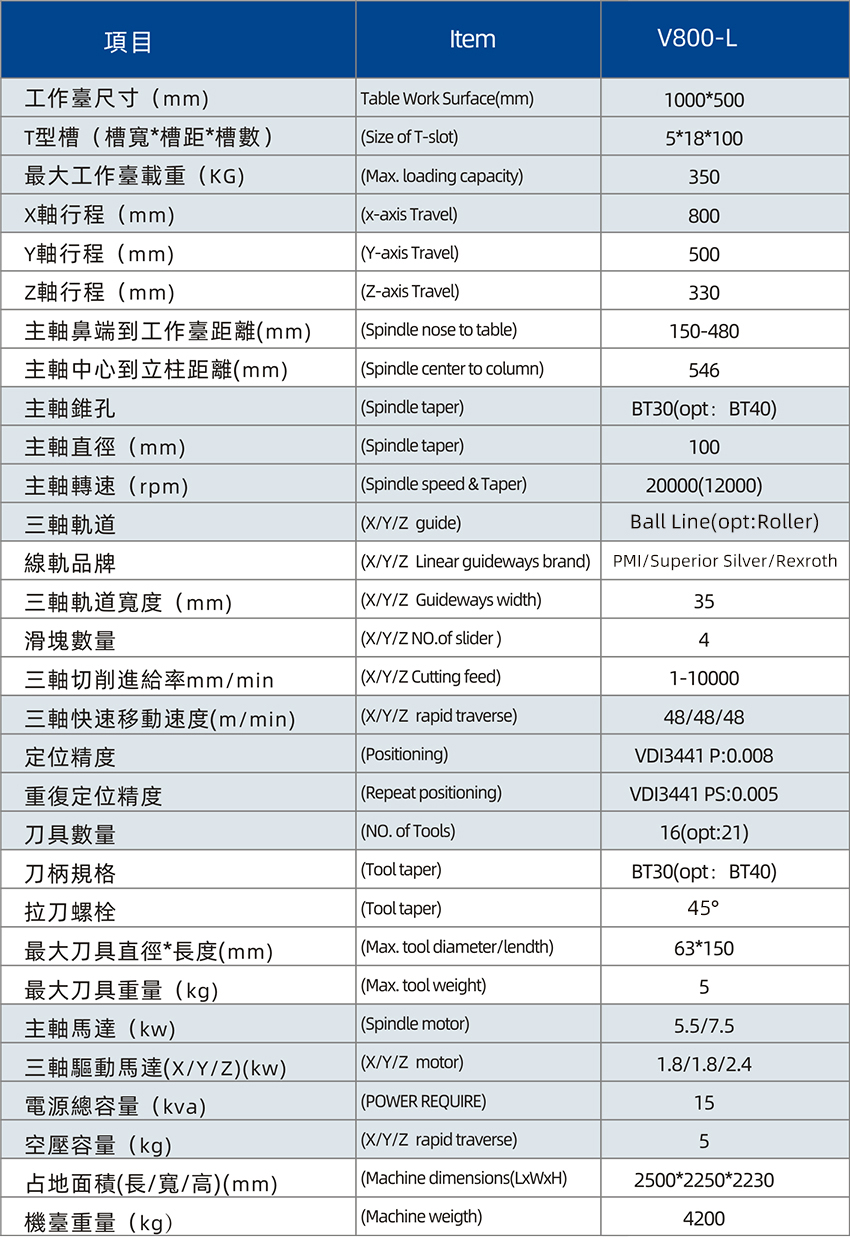

Mechanical Specification Sheet

Standard Accessories

● Belt head (BT40) 10000rpm spindle

● 24 knives A.T.C (knife arm type)

● waterplane

● Fully enclosed shield

● working lamp

● Central Lubrication System

● Operation indicator

● Spindle ring blowing (belt type)

● Tools and Toolbox

● Rear chip washing device

● Working cleaning gun

● water gun

● Level adjustment block and leveling screw

● Electric box heat exchanger

● Chip blowing device

● Spindle oil temperature cooling device

● Operating instructions with parts list

● Spindle 4-hole water spray (belt type)

Special Accessories

|

● BBT-40 broach screw ● Belt type 8000rpm spindle ● Direct-coupled spindle 12000/15000rpm ● 20bar high pressure spindle ● water outlet ● 32 knife arm type

● Complete set of four/five-axis rotary table

● Automatic shutdown device ● Automatic tool length measurement ● Oil-water separator ● Crawler chip remover ● Oil mist recovery device |

|